THESE ARE THE DAYS, as the traveling troubadour once sang, of miracle and wonder. The technological and mechanical marvels all around us are such a part of our lives now that we barely notice them, except—for some obvious ones, at any rate—to lament their pervasive, all- consuming, almost suffocating influence.

Not so the 10 electrifying new products on the pages ahead. The 2020 nominees for Edison Awards in the dental category, these innovative devices, gadgets, time savers and efficiency heighteners cover the practicing dentist in every conceivable way around the operatory and the office space.

It’s easy to grouse about the ubiquity of today’s technology, but these dazzling innovations represent the best of the spirit of inquiry and problem-solving that tech (and medicine, lest we forget) inherently seem to inculcate. Better syringes, at-home denture molds, the finest whitening system now available, flawless and quick sterilization units: The brightest minds of the dental industry can make it all happen. Congratulations to all of this year’s nominees—the future of dentistry begins right here.

For more information about the Edisons and to review nominees from other industries, please visit edisonawards.com.

SINCE 1987, the Edison Awards have recognized and honored some of the most innovative new products, services and business leaders in the world. The Awards are named for Thomas Alva Edison (1847-1931), whose extraordinary new product- and market-development methods garnered him 1,093 patents and made him a household name around the world. The Edison Awards symbolize the persistence and excellence personified by Edison himself, while also strengthening the human drive for innovation, creativity and ingenuity.

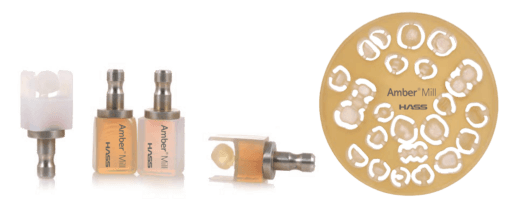

Amber Mill

HASS BIO

Inventor: Ryan Lee

THE UTTERLY NANO—as in 0.1-micrometer nano-lithium disilicate crystalline Amber Mill offers doctors something totally toothsome: glass-ceramic dental blocks that are second only to real teeth. Made for CAD/CAM systems, Amber Mill boasts excellent machinability, reinforced mechanics and beautiful aesthetics.

THE UTTERLY NANO—as in 0.1-micrometer nano-lithium disilicate crystalline Amber Mill offers doctors something totally toothsome: glass-ceramic dental blocks that are second only to real teeth. Made for CAD/CAM systems, Amber Mill boasts excellent machinability, reinforced mechanics and beautiful aesthetics.

Small but mighty, the dense, cross-linked crystal structure is durable, with biaxial flexural strength some 10 percent greater than comparable products when fully crystallized. Its high edge stability is unmatched, with less chipping when milled, and its opalescence mimics that of real teeth better than anything outside of God’s own dental lab. It appears blue (bluish, anyway) under reflected light, and yellowish under transmitted light.

It also gives dentists the freedom of translucency via heat treatment. “This helps you enhance the efficiency of your inventory management and work process for millable blocks,” says its inventor, Hass Bio’s Ryan Lee. When you’ve determined the correct shade, choose its paired translucency temperature for beautiful results. The material has “a natural opalescence and fluorescence,” Lee observes. Indeed, it’s utterly realistic—an important trait for increasingly savvy, choosy patients who know they can get something every bit as good as the genuine article from a capable dental practitioner.

“The patient has more control,” Lee adds—and a patient in control is a more satisfied patient. (“Hass” stands for “Human Aid System Supplier,” after all.) “It’s a game changer in restoration for dentists,” Lee says. “If they use the Amber Mill, patients will love their crown.”

Armor

AIR/WATER SYRINGE TIP AND SLEEVE COMBO

PAC-DENT

Inventor: Daniel Wang

YOU CAN MAKE a case that there’s no better innovation than one that renders an existing process or product more efficient. For example: the Armor Air/Water Syringe Tip and Sleeve Combo, which simplifies the assembly of a syringe tip and sleeve from two steps into one.

YOU CAN MAKE a case that there’s no better innovation than one that renders an existing process or product more efficient. For example: the Armor Air/Water Syringe Tip and Sleeve Combo, which simplifies the assembly of a syringe tip and sleeve from two steps into one.

Dr. Daniel Wang, 64, the CEO of Pac-Dent—a dental-products manufacturer in Brea, California, just outside Los Angeles—came up with the idea for a combination syringe and sleeve in 2018. The company then unveiled it in 2019 at the Midwinter Meeting in Chicago, and as of January had already shipped a half-million units to market.

“The entire industry is focusing more on infection control,” says Pac-Dent’s Sara Qu. “The [Armor Air/Water] gives clinicians peace of mind and more control over cross-contamination.” To use it, insert the sleeve-covered syringe into your instrument (the nonslip sleeve is made with special copolymer film for infection control) and lock it in place, then slide the sleeve over the syringe and instrument. Just like that, your patient is protected from cross-contaminated air and water during cleaning and other procedures.

It’s clean and sanitary—and fits better than ever. “A lot of times you see a bulky sleeve cover, so we tailor-made the sizes to fit that exact syringe that sprays the air and water,” Qu says—a guard against dropped instruments, and an environmental boon given that it requires less plastic, too.

Easy Denture

OTERO FAMILY, COSMETIC & IMPLANT DENTISTRY

Inventor: Dr. Misael Otero

SOME THINGS—the wheel and sliced bread come readily to mind—don’t warrant reinvention. Others, like the denture, whose roots go back to 700 b.c., were long overdue for a rethink. Then came Wilmington, North Carolina, dentist Dr. Misael Otero and his Easy Denture.

SOME THINGS—the wheel and sliced bread come readily to mind—don’t warrant reinvention. Others, like the denture, whose roots go back to 700 b.c., were long overdue for a rethink. Then came Wilmington, North Carolina, dentist Dr. Misael Otero and his Easy Denture.

The current century has been a time of enormous technological change, but replacement teeth, by and large, have remained archaic. “We needed a fast, more convenient and cost-effective way to get people dentures,” says Dr. Otero, 41, who owns his practice with his wife, Dr. Lindsey Otero.

The number shocks: Nearly 40 million Americans are missing all their choppers. “It’s like a forgotten population—we’re talking about an eighth of the population without teeth,” Dr. Misael Otero observes. “When you go to the store, Fixodent is at the bottom, but there’s a whole lineup of whitening products at eye level.”

The patented, heat-moldable Easy Denture looks as sophisticated as any modern iteration, yet it can be fitted—and, crucially, refitted by people at home—in just five minutes. The universal-fit boil-and-bite apparatus is made of three layers of Nuvoflex and Nuvoflex Stretch (“almost like Play-Doh,” Dr. Otero says) that, after spending just a few minutes in a water bath, can be reheated as many times as needed to get it just right.

Now, instead of fitting one or two patients a day for dentures, a doctor can conceivably tackle dozens more. In addition, Easy Denture will help people avoid multiple uncomfortable, all-day visits to a clinic or practice and, at $500 per arch, spending hundreds or even thousands of dollars. “I invented it with the patient in mind,” Dr. Otero says. An improvement on a longstanding product, in other words—proof that even the most Edison-worthy innovations don’t necessarily emerge from nothing.

GantGuard

DENTAL AND SURGICAL BIB

GANT MEDICAL

Inventor: Christian Viviers

IT ALL STARTED, like so many brilliant ideas, with a napkin.

IT ALL STARTED, like so many brilliant ideas, with a napkin.

Christian Viviers met scientist Gail Shaw in 2014 at a trade show, where she was pitching her idea for a self-adhesive napkin with a special glue to improve its ability to stick cleanly. Viviers, now CEO of Alpharetta, Georgia–based Gant Medical, spent six months contemplating how to use Shaw’s adhesive before creating a new kind of medical bib that would replace not just the typical dental bib but chains, alligator clips and sanitation wipes, too.

“It was ignored for a long time,” Viviers, 55, says. “People thought, ‘What can you do with a bib?’ ” Quite a bit, it turns out. The bib may not be the sexiest item, but its ability to prevent the spread of bacteria and contain blood and other fluids is critical. The chains and clips that secure traditional bibs are reusable—and therefore vulnerable to contamination. According to one recent study, one in five dental clips was infected with potential pathogens.

The disposable GantGuard circumvents sterility altogether. Grab one from a roll on the counter or a dispenser on the wall, pull apart at the perforated neck opening and stick its patented nontoxic adhesive to a patient’s skin or clothing. It provides a better patient experience—no more icy alligator clips grazing the skin—and, at nearly twice the size of most medical bibs, keeps clothing free of stains. (It’s available in both pediatric and adult sizes.)

“We’ve been told over and over at trade shows that it’s the best product of the show,” Viviers notes proudly. Sanitary, economical and space-saving: We can see why.

glo

LIT TEETH WHITENING TECH KIT

GLO SCIENCE

Inventor: Dr. Jonathan B. Levine

THE GOOD DR. LEVINE has been working to improve teeth whitening for years. The Manhattan entrepreneur and prosthodontist has invented 20 dental products and holds 27 patents. He has also been nominated for four Edison Awards. “I think of my office as a laboratory,” he says—and his latest creation, a Bluetooth-enabled teeth-whitening device, is decidedly futuristic.

THE GOOD DR. LEVINE has been working to improve teeth whitening for years. The Manhattan entrepreneur and prosthodontist has invented 20 dental products and holds 27 patents. He has also been nominated for four Edison Awards. “I think of my office as a laboratory,” he says—and his latest creation, a Bluetooth-enabled teeth-whitening device, is decidedly futuristic.

“In the early days, the gel-and-tray whitening process was slow and painful,” says Dr. Levine, who has been practicing for 30 years. Light curing, while an improvement, presented some of the same problems. Why not, the doctor thought, take the best of both worlds?

Enter the GLO Lit Teeth Whitening Tech Kit, the only at-home whitener to combine both blue LED light and heat. Its closed-tray system prevents oxygen from escaping, cutting the typical 20-minute cycle to just eight.

The $149 kit comes with a universal mouthpiece, seven vials of dripless hydrogen peroxide whitening gel, a Bluetooth power pack, a GLO Heat & LED Light Mouthpiece and storage case, plus a special balm to help prevent any irritation to the lips. The power pack, which can fit in the user’s pocket, clip to clothing or hang from the lanyard that comes with the kit, controls the temperature, helping the at-home user avoid unpleasant “zingers” (the tinny shots of pain often associated with teeth whitening).

Though the “GLO Whitening” app isn’t necessary to use the product, its smart technology is beneficial, offering a preview of results, helping schedule treatments, setting reminders and tracking progress as you go. “It talks to your phone, helping you know what the regimen needs to be,” Dr. Levine says.

Green Light

DENTAL COMPLIANCE CENTER

HU-FRIEDY

Inventors: The IMS and Infection Prevention Team at Hu-Friedy

RESTAURANTS HAVE TO POST that pesky employees must wash hands sign in their bathrooms, but for dental practices, uniform state and federal guidelines for infection prevention can seem vague or even nonexistent.

RESTAURANTS HAVE TO POST that pesky employees must wash hands sign in their bathrooms, but for dental practices, uniform state and federal guidelines for infection prevention can seem vague or even nonexistent.

“Compliance is one of those things that is still ana-log in the digital world,” says Jessica Wilson, business development manager at Chicago-based Hu-Friedy. “There are still a high percentage of practices that don’t have written protocols.”

Hu-Friedy, a manufacturer of dental tools since 1908, has long offered a “sterilization observation” service that will grade a practice’s compliance. “After doing hundreds of these [observations] over the years, we started to see gaps in the market,” Wilson says. The company’s IMS (Instrument Management System) and Infection Prevention Team took the online evaluation questionnaire they were already using, and developed it into an online portal for practices’ internal use.

It asks a series of pointed questions—about designated infection-control coordinators, water sources, waste disposal and much more—and, at the end, spits out a 170-page-plus document with customized, streamlined compliance protocols. “The thought is to take the complexity out of managing a compliance center,” Wilson says. “In one hour, you can get a fully complete compliance manual.”

The need seems to be acute. A 2018 study of the subject by Hu-Friedy produced some surprising results: More than 65 percent of surveyed practices did not meet OSHA or Centers for Disease Control recommendations for sterilization monitoring, 36 percent moved loose contaminated instruments by tray and 29 percent used bare hands to clean instruments for sterilization. “There’s still a lot of institutional memory in dentistry, and the information is not necessarily best practice or manufacturers’ guidelines,” Wilson says. “This opens practices up to more risk exposure.”

GreenLight’s reporting dashboard keeps records of all compliance, however—and merely having a written protocol, Wilson says, can help protect a dental practice from potential legal ramifications. The portal’s records last forever, can’t be falsified and are accessible by Hu-Friedy’s leadership team should there ever be a dispute. “GreenLight is unique in that we’re teaching people how to manage compliance digitally,” Wilson says. “It’s a market disruptor.”

nano

95LS ELECTRIC HANDPIECE

NSK AMERICA

Inventors: The NSK Dental Product Team

ABOUT A THIRD of today’s working dentists—some 64,000—are women, and the number is only going up. Yet manufacturers have been slow to cater to female clinicians. For Colan Rogers, the president of NSK America, there’s an obvious gap between what female dentists want and what’s available. “The demographics have been changing for a long time,” he says. “There was definitely a space for us to focus on the female practitioner.”

ABOUT A THIRD of today’s working dentists—some 64,000—are women, and the number is only going up. Yet manufacturers have been slow to cater to female clinicians. For Colan Rogers, the president of NSK America, there’s an obvious gap between what female dentists want and what’s available. “The demographics have been changing for a long time,” he says. “There was definitely a space for us to focus on the female practitioner.”

Rogers knew just where to start: with the Nano 95LS Electric Handpiece, a smaller, lighter version of the company’s Ti-Max Z Series. The Nano 95LS was successfully developed and launched in Japan, where NSK is headquartered, in 2015, and brought to the U.S. in September 2019. (The company’s American base is just outside Chicago.)

“Part of the challenge of the female dentist is the size and weight of handpieces,” Rog-ers says. The Nano 95LS offers the same bells and whistles as the Ti-Max Z Series—it’s made of titanium and has ceramic bearings, DLC coating, cellular glass optics and a microfilter—in an instrument four grams lighter and 10 millimeters shorter than the Ti-Max Z. Yet its point of balance is the same as other NSK handpieces, making it highly maneuverable for dentists with smaller hands or shorter fingers.

Use of electric handpieces is growing by 35 percent a year, and it’s taught in at least half of dental schools, a majority of whose graduates are women. NSK, the world’s largest manufacturer of handpieces, would seem to be well-placed for the changing profile of dentists in the years ahead.

pineyro

ARCH KIT

PARADISE DENTAL TECHNOLOGIES

Inventor: Dr. Alfonso Piñeyro

ONE DAY IN 2016, prosthodontist and implant educator Dr. Alfonso Piñeyro experienced an entrepreneur’s classic light-bulb moment. For the umpteenth time, he was explaining during a lecture that the only hygiene tools available for implants are the same ones used in standard cleaning. “There were implant-specific instruments on the market, but the only thing that makes them [suitable] for implants is that they’re [made] of titanium instead of stainless steel,” Dr. Piñeyro, 42, explains. “They don’t accommodate for the different substructures of implants. I knew there had to be a better way.”

ONE DAY IN 2016, prosthodontist and implant educator Dr. Alfonso Piñeyro experienced an entrepreneur’s classic light-bulb moment. For the umpteenth time, he was explaining during a lecture that the only hygiene tools available for implants are the same ones used in standard cleaning. “There were implant-specific instruments on the market, but the only thing that makes them [suitable] for implants is that they’re [made] of titanium instead of stainless steel,” Dr. Piñeyro, 42, explains. “They don’t accommodate for the different substructures of implants. I knew there had to be a better way.”

The Seattle-based dentist found it, developing the Pineyro Arch Kit with Paradise Dental Technologies, a manufacturer in Missoula, Montana. The four tools in the kit are titanium to preserve the integrity of the prosthetic teeth, but unlike traditional scalers, curettes and other hygiene instruments, the Pineyro counterparts have an arch, or semicircular shape, that enables them to adapt to the implant components, and a flat profile that permits access between the gum and the implants.

Each mouth and implant is different, of course, but the abutment component for every implant fixture has a universal diameter, which Dr. Piñeyro copied for his eponymous kit. The equivalent size allows the instruments to painlessly access the areas where plaque and other buildup occur.

“One of the biggest frustrations is that [prosthetics are] a lifetime solution,” Dr. Piñeyro notes. “However, there still needs to be maintenance, which is done by hygienists who have very little training in these prostheses and their components.” The Arch Kit’s tools, by contrast, make it easy: They can be locked in place and rotated or moved up and down—an entirely different movement than in traditional cleaning, but simple to learn. Not only do prosthodontists and hygienists save time with the Pineyro Arch Kit, but patients get a deep, flawless clean. The doctor’s proverbial light bulb, it seems, glows on.

Soft Bite Block

RICHMOND DENTAL & MEDICAL PRODUCTS

Inventor: Diana Roloff

EVERYONE’S ALL FOR the do-it-yourself spirit when it comes to saving money on home renovation, say, but for one’s precious mouth? Not so much, surely. Yet that’s how mouth props and bite blocks have been done for decades.

EVERYONE’S ALL FOR the do-it-yourself spirit when it comes to saving money on home renovation, say, but for one’s precious mouth? Not so much, surely. Yet that’s how mouth props and bite blocks have been done for decades.

Nurse anesthetist Diana Roloff, 69, who has been in the pleasant- sounding business of anesthesia since 1989, wanted to change that. “In the 1990s, nurses would make 100 of these DIY bite blocks, and put them in a cart in a hospital room. Who knows how many CRNAs were reaching in to grab some?” Roloff says. “You had no idea of controlling the environment or knowing if it was clean.” After decades working as a CRNA in North Dakota, Roloff couldn’t believe that a better option still hadn’t been invented—so she decided to make one herself.

She and her two sisters spent months cold-calling companies to pitch a premade sanitary bite block. Finally they reached Richmond Dental & Medical in Charlotte, North Carolina, which loved the idea.

The dense tube of medical-grade cotton is bound tightly in silk yarn. “[Bite blocks] should always be readily available,” Roloff says. “If you’re stepping away to make something to bite down on, that’s time that patients could be harming themselves.”

The dental industry will surely laud them: A fourth of anesthesia-related insurance claims have to do with dental harm. It gives new meaning to preventative dental care, doesn’t it?

Statclave G4

SCICAN

Inventors: The Business Development Team at SciCan Inc.

COMPLIANCE IS of the utmost importance in dentistry, and it just might be the buzzword of this year’s Edison nominees, too. Juggling the requirements of OSHA, the CDC and other governing bodies is no easy feat, and maintaining clean tools is a nonnegotiable first step.

COMPLIANCE IS of the utmost importance in dentistry, and it just might be the buzzword of this year’s Edison nominees, too. Juggling the requirements of OSHA, the CDC and other governing bodies is no easy feat, and maintaining clean tools is a nonnegotiable first step.

“Generally, we found that offices are struggling to keep up with the throughput of instruments,” says Stacey Graf, product manager for SciCan, the Canonsburg, Pennsylvania–based infection-control company that debuted the Statim autoclave in the 1980s. “Nobody wants to stay late to sterilize instruments because they don’t have the right equipment for their workload.”

SciCan set out to produce a bigger, better, more modern version of the industry-altering Statim. The result is the StatClave G4, which received FDA approval this past autumn. “Industry leaders have been looking for a large sterilizer that was also fast and able to dry instruments effectively,” Graf says. “With the StatClave, we focused on having both: dryness and speed.”

The StatClave G4’s 11-inch chamber makes it one of the largest on the market. It can hold four 8-by-11-inch cassettes or about 20 pouches, and, using vacuum technology, takes just 38 minutes from start to finish—25 minutes less than similarly sized products. Plus, the pesky problem of still-moist tools after a sterilization cycle is eliminated. “We’re talking completely bone-dry,” Graf says.

The device is smart—that is, it can connect to the internet, too. Its G4 technology stores a memory of each sterilization cycle in the cloud that clinicians can log into the portal to see. (Another record-keeping win for compliance.) In the event of a system failure, SciCan will be sent a message and reach out to the office to help solve the problem. “The StatClave will help avoid bottlenecks in the sterilization process,” Graf says. “Patients aren’t waiting for clean tools, and staff can go home on time.” We’ll toast to that.

JERILYN FORSYTHE is a writer in Florida whose work appears

regularly in Incisal Edge.

DENTAL INNOVATORS

HALL OF FAME

THERE ARE Edison Award winners, and then there are those whose entire career, spent in the service and advancement of dentistry, qualifies them for even greater honors. Incisal Edge is proud to welcome one new inductee into this heralded group for 2020.

2020 inductee

BERNARD WEISSMAN

By Dr. Howard Strassler

Bernard—everyone calls him Bernie—is the

epitome of a life well-lived. Having left Europe

during World War II, he made it to the United States, where he trained as a dental laboratory technician. That training helped him see and understand the challenges dentists faced every day.

He has long possessed a mechanical, innovative view into how dental services are—and ought to be—provided to patients. Caries were far more prevalent in the 1950s and ’60s. Dentists were restoring teeth with direct restorative materials, mostly amalgam, that required large preparations and lacked today’s bonding benefits. Through his first company, Whaledent, Bernie provided an innovative solution to restore teeth and retain those restorations via posts and screw-type pins.

The earliest pins required large channels and were cemented in place. Bernie’s understanding of the physical structure and histology of dentin enabled him to develop a pin that screwed into the dentin without harming it. To make pins that small, you need a machine. As its foundation, Whaledent had innovative ways to restore teeth safely—creative designs with posts for endodontically treated teeth and pins placed using a handpiece. All of them crucial Bernie Weissman inventions that changed restorative dentistry.

After he sold Whaeldent, he returned to the industry by acquiring Dentatus USA in 1988. Working with prosthodontists, he and his company developed the first mini-transitional implants—transforming implant placement from a surgical procedure requiring months (for certain clinical situations, at any rate) to mere small, atraumatic implants that could be restored immediately.

My favorite memories of Bernie, who is now 94, entail meeting him in New York for the day and spending all our time in the workshop. He’s always tinkering with inventions and changes to existing technologies. One needs only 15 minutes with Bernie to get a glimpse of the future of dentistry. He’s revered internationally for his accomplishments, and I’m proud to call him my friend.

Dr. Howard Strassler is a member of the Incisal Edge Editorial Advisory Board.

2019

ESTHER WILKINS

Author of Clinical Practice of the Dental Hygienist, an industry bible first published in 1959, now in its eleventh edition. Dr. Wilkins won the Lucy Hobbs Industry Icon Award in 2015.

2018

DR. FRANCIS MOUYEN

This French inventor developed the first digital imaging system specifically for dentists, debuting it in Switzerland in 1987.

2017

DR. RAFAEL BOWEN

Invented the first truly effective resin-based dental composite, which he introduced in the 1960s; he also played a big role in the development of sealants.

DAVID SCHICK

Inventor of the Schick Sensor, the first technology that enabled dentists to create and view large, clear intraoral images while exposing patients to much less radiation than X-rays.

2016

DR. RICHARD PELTON AND ERNEST CRANE

Pelton and Crane’s eponymous industry giant got its start as a modest two-man operation back in 1900. Now, 120 years later, their names remain a byword for dental quality.

GORDON J. CHRISTENSEN

An educational giant, Dr. Christensen founded Practical Clinical Courses, a continuing-education company for dental students worldwide.

2015

DR. ROBERT MEYER

President of the DentalEZ Group and a pioneer in the development of 100 percent water-free vacuum devices, dental separation tanks and much more.

DR. LUCY HOBBS

The first American woman to earn a dental degree when she did so in 1866, Dr. Hobbs is the inspiration for Benco Dental’s Lucy Hobbs Project.

2014

DR. JACK DILLENBERG

The inaugural dean of the Arizona School of Dentistry & Oral Health at A.T. Still University in Mesa.

DR. HOWARD FARRAN

Phoenix-based dentist and MBA; founder and publisher of Dentaltown magazine and Dentaltown.com.

2013

DR. WILLIAM B. DRAGAN

Founded Centrix in 1970. He developed products including the Mark I, II and III syringes, composite-resin tubes and plugs, and more.

DR. JOHN V. BORDEN

Enlisted in the Navy as a dental surgeon and served in both the Atlantic and Pacific theaters during World War II. Inventor of the Borden Air-Rotor.

2012

DR. JOSHUA FRIEDMAN

Founder and CEO of dental- product manger AdDent and a dental-technology pioneer.

JIM GLIDEWELL

Founded Glidewell Dental Laboratories in 1970 and made it into an industry leader in crowns, bridges, ceramics and much more.