Meet some of dentistry’s fastest-thinking, status-quo-smashing product maestros. Their endless ideas and relentless curiosity keep our industry marching toward a smarter future—while keeping their competition up at night. Here’s how they do it, and why it matters.

Yamato Inoue

Manager, Dental Design Department, NSK

Tochigi, Japan

Education: Master’s in mechanical engineering, Graduate School of Engineering, Nagaoka University of Technology, 2012

POSITIVE THINKING is a must for Yamato Inoue. After all, he’s in charge of designing handpieces, for which high precision is at odds with the wear and tear they endure. His secret? “Turn pressure into positive energy that propels me forward.” If his finished products are any indication, that strategy is working.

Take NSK’s recently launched Ti-Max Z990L/Z890L high-speed turbine, with the world’s highest power, 44W, for cutting harder materials such as zirconia. Inoue describes two technical challenges: first, improving energy conversion efficiency using computational fluid-dynamics simulations, through which NSK “improved the output at the same air pressure compared to conventional products.” Second, achieving lower rotational speed and higher torque. “The durability of a high-speed air turbine is majorly affected by its rotational speed, so if the rotational speed can be lowered, it can be used at higher supply pressures.” You’d think that would be extra finicky to service, but the cartridge is user-replaceable.

Some of the pressure to produce increasingly sophisticated handpieces comes from Inoue himself. “Simply meeting customers’ expectations is not enough to make progress,” he says. In the case of the Z990L/Z890L, it seems he succeeded. One user, author and lecturer Dr. Ron Kaminer, calls them “a total game changer. Weightless in the hand, clear-directed water spray and decibels lower than most high speeds.” Another, educator and speaker Dr. Foroud Hakim, says he always says to colleagues, “ ‘It’s hard to practice to our fullest potential without electric handpieces. This line is a marvel of engineering and design.’ ”

Inoue’s personal favorite is the S-Max M800/M900 series. “This was the first air turbine handpiece I was involved in designing, and it gave me the opportunity to take off as a designer.” This was by no means a cost-is-no-object exercise. On the contrary, Inoue says, a major constraint was maintaining cartridge compatibility with older products while improving power output—and reducing costs. “We introduced high-performance CFD simulation and rebuilt the simulation method from scratch. The internal structure of the body was redesigned from scratch. This has been optimized to the maximum extent possible within major constraints.”

Inoue’s research typically unfolds in two ways. One is a top-down approach, “where the task is to develop a specific product or feature to meet users’ requirements.” The other is bottom-up, “when engineers discover the possibility of increasing the added value of a product by further developing established technology, or by combining it with other technologies. I tend to start with the latter method.” Engineers determine technical feasibility using prototypes, gathering feedback from internal and external experts (including shadowing dentists), then deciding whether they have a viable product or need to go back to the drawing board.

While Inoue’s colleagues usually work in teams, “the project leader has absolute discretion. Air turbines have a simple structure, with only about 60 parts. A single designer can reflect his or her thoughts and ideas in the design as desired.” It’s exacting, sometimes solitary work. “You’ll be working on your computer all day. This is a repeated process of creating a 3D model using CAD and checking its performance using CFD simulation.” More often than not, it’s back to the drawing board, but Inoue says it’s worth it to feel “a great sense of accomplishment” when things eventually go right.

The challenges keep coming. To cite just one perpetual obstacle: the conflicting desire to combine the form factor of a smaller head for visibility and accessibility with the power of a larger head that reduces treatment time. “A small head and high power are technically contradictory,” Inoue says. “The fact that there are multiple lineups of head sizes in the market shows that technology that completely satisfies users’ requirements has not yet been established. We will continue to take on the challenge of achieving these technical elements.

Development always progresses under pressure from many directions, but this should not be seen as a negative thing.”

Sung-Il Choi

Chief Technology Officer, Vatech

Seoul, South Korea

Education: MS, biomedical engineering, Yonsei University (1999–2004); Ph.D, radiology science, Yonsei University (2004-08)

SUNG-IL CHOI CAUGHT a rocket ride with one of dentistry’s fastest-growing, most innovative companies. “My childhood dream was to become a scientist,” he says. Still, it wasn’t all that long ago that he struggled to find a professional home for his talents. “In college, I majored in biomedical engineering and X-ray physics. There aren’t many companies in Korea that can utilize this kind of expertise. As I watched [Vatech] grow, I decided to grow together with it.”

Choi characterizes the company’s R&D operation as a “private research institute,” an apt description given its structure as well as its close association with institutes of higher learning. He began working with Vatech while pursuing his Ph.D. starting in 2005, serving as principal research engineer at the Vatech–Yonsei University collaborative imaging research center in Seoul before ascending to his current role in 2010.

Perhaps one reason why a relatively young company like Vatech has so quickly gained a prominent position in dental imaging is its disciplined focus. It operates individual research labs for core components like sensors, generators, systems and software, with Choi overseeing a team of 60 as head of the systems lab.

Another reason: a people-centric approach. On a macro level, Choi says, “low dose [is] the core value.” From there, “people are always at the foundation of defining development lists. Our customers are very diverse.” Choi’s definition of “customer” is actually closer to “stakeholder,” taking into account everyone touched by the product, from purchasers to users to patients and even service personnel.

Currently, Choi and his colleagues are preparing the next generation of products with some special concerns. He acknowledges that “technological advancement in the medical field is faster than that of diagnostic equipment in the dental field.”

With that in mind, one job is delivering solutions with “the performance of medical products while having a price and equipment structure that can be adopted in the dental field.” Another is using technology to address the needs of a graying population. “The scope of diagnosis has expanded from traditional implant treatments to include more aesthetic treatment and temporomandibular joint treatment. As the diagnostic field expands, we believe the performance of X-ray equipment also needs to go beyond its previous limits.”

Daunting? Yes, but Choi is in it for the long haul. “I believe Vatech will be my first and last company. Now that I’m developing products in an R&D department, my childhood dream has come true. The products I make are like my children.”

People are always at the foundation of defining development lists.

Austin Unsworth

Director of Development and Innovation, DCI

Newberg, Oregon

Education: BFA in industrial design, Brigham Young University, 1998

SOME PRODUCTS we rarely touch. Others we interact with frequently, closely and even kind of intimately. It’s fine if a decorative vase on a bookshelf is fragile because we mostly just look at it. A mobile phone, on the other hand, must look good, feel good, be inviting, durable and more. Dental equipment is far more mobile phone than fragile vase. That’s easy to understand but hard to apply—but Unsworth has just the résumé for it, with both deep experience in dental equipment design from a user’s perspective, as well as a wider perspective provided by his time at IBM and an industrial design consultancy. That experience “inspired in me a desire to use design to improve lives with beauty and simplicity,” he says. He’s responsible for innovations like the first LED operatory light; he also has a drawerful of patent applications bearing his name.

If it sounds like he’s leading a team who stare at schematics all day and scratch their chins in deep contemplation, the reality is rather different. “Our group focuses on a fast time to market from concept to introduction,” he says. “Some products can be developed in six months or less.” Which makes sense in a competitive business environment. Why sit on improvements if you can get them to market faster and compete more aggressively? “Each new concept is quickly prototyped and tested using various fast-turnaround prototyping processes and in-house testing facilities. We constantly challenge ourselves to find the simplest solutions that solve the problems at hand. This leads to cost-effective innovations and visually appealing product solutions.”

Don’t confuse fast with rushed, though. The more experience people have, the less time they spend figuring out how to do things versus actually doing them. DCI was already manufacturing the innards for a number of delivery systems before it started marketing its own line of operatory equipment in the 1990s, and Unsworth previously developed the 3000 line for Pelton & Crane. He and his team bring much more than industry experience to the table—and they spread it around. “Every engineer takes on all roles and responsibilities of the group, including concept developer, prototype designer, test fixture designer, prototype tester, part and assembly designer, supplier collaborator and product schedule tracker,” he says. One result: Every prototype is thoroughly vetted. And the product isn’t done until it’s truly done, even if that means eleventh-hour changes.

His baby thus far is DCI Edge “because of the opportunity it has been to start with a clean slate and develop innovative solutions that meet our customers’ needs with beautiful and durable designs.” It’s just one example of how being fast with new ideas, fast to bring them to market and extremely competitive on price all stoke success. Does the pressure to constantly one-up himself ever get exhausting? It does not, he insists. “It’s the constant challenge that keeps my work interesting.”

We constantly challenge ourselves to find the simplest solutions that solve the problems at hand. This leads to cost-effective innovations and visually appealing product solutions.

Derek Pereira

Vice President, R&D, SciCan

Toronto, Ontario

Education: Bachelor of engineering in electrical engineering, Toronto Metropolitan University (formerly Ryerson University), 1999

AUTOMATING instrument processing is a win for any practice, cutting down on costly, boring manual labor by staff who could be doing more complex work. But getting there requires equipment like instrument washers that are both smart and fast. The questions people ask: How do electronics and software influence a mechanical process that’s getting faster all the time but also somewhat limited by physics? And how can IoT and AI make operating and maintaining these devices easier and more reliable?

“Technology has replaced electromechanical timers and sensors with electronics and next-generation sensors,” explains SciCan’s Derek Pereira, who leads a team of 50 engineering and design professionals encompassing mechanics, electronics, IoT, software, web/cloud, product testing and more. “Today’s electronics and sensors provide the data for the software to control the operation of the device. Some systems can adjust in microseconds—1 million actions/adjustments in one second—and often better. Even though modern sterilization parameters are well defined, engineers now have more control and can change how the device works to minimize wasted time and energy in the system.”

SciCan uses its Wi-Fi-enabled G4 technology to send cycle data to smart devices or computers, so team members can focus on patients while monitoring their stericenters. This is where the addition of AI and machine learning will soon come in. “This technology can be deployed everywhere from intelligent chatbots that can provide replies to common questions and solutions to get the customer up and running quickly, to digital services that would alert users when a device or component might be underperforming and needs an in-person service call,” Pereira says. That’s important because the company designs for long product life. “Many Coltene/SciCan products have been in operation for more than seven years, and some have been in operation for over two decades. During our design process, we make significant effort to reuse components over and over—and if that’s not possible, we look for alternate components that can be used as ‘drop in’ replacements and smaller ecological footprints.”

To that end, Pereira says, “All our newer products are designed to use less electricity and water and/or wash chemicals during sterilization and washing, respectively.” Earlier innovations included a feature that enabled SciCan devices to be prewarmed at predetermined times to avoid excess electricity consumption. While durable design and easy repairability extend product life, nothing lasts forever. SciCan also designs its products for recycling, and even the packaging in which they’re shipped are designed to be as recyclable as possible.

What does the future hold? For one, Pereira feels that certain AI applications such as “using [it] to automatically validate sterilization parameters and indicate if the cycle was successful” are still a way off, mainly due to a lack of widespread understanding and acceptance. On the other hand, “We are continuously investing in the user experience. We have invested in our digital services and our cloud platform.” That platform will allow for automated recordkeeping; digital twin modeling of physical processes for testing, monitoring and maintenance; and remote access. “The G4+ devices will provide a new level of integration we have not seen before.”

Pereira has wound a professional path through a veritable who’s-who of top employers, from GE Healthcare to L3Harris air and space technologies, before settling at SciCan five years ago. He loves the collaborative aspects of R&D. “Dreaming up how we can use these technologies to make the next generation of products, then seeing our customers use them, is incredibly rewarding.”

He’s tight-lipped about what we can expect down the road from SciCan but drops some exciting hints. “The next breakthrough could reside with machine learning, artificial intelligence and possibly quantum computing or using robotics during the instrument reprocessing workflow.”

IoT and digital services are a growth path for our business and an emerging, and overdue, technology in our industry.

Thorsten Bock

Director, R&D Organic, Ivoclar

Schaan, Liechtenstein

Education: Doctor of chemistry from the University of Freiburg (Germany), specializing in polymer chemistry, 2007

ISOLATION IS A bad thing when someone—politician, engineer, scientist—serves a large constituency. Luckily, Ivoclar’s Thorsten Bock doesn’t work in an ivory tower. He’s part of a corporate culture closely connected to the practicalities of the products he helps bring to life. For example, a big problem found its way to him several years ago during a regular meeting with U.S. colleagues at Ivoclar headquarters in Schaan. “They said zirconia restorations were failing when using Monobond Plus. Well, I know Monobond Plus works with zirconia because I developed it.” He probed deeper and found that after intraoral try-in, dentists were “cleaning” the restoration surfaces with phosphoric acid. “I’d never heard that before. Zirconium oxide reacts with phosphates in very determined manner, passivating the surface. Still, the proteins deposited on the zirconia surface by saliva contact must be removed safely in a procedure compatible with standard in-office equipment.”

That was the beginning of the development of Ivoclean, the first product of its kind. “What grew out of that meeting was, dentistry started talking about strictly avoiding contact of phosphoric acid with oxide ceramics. And the end was, we cleaned monolithic zirconium oxide with a zirconium oxide dispersion.” It’s part of what should be an ongoing conversation between manufacturers and dentists. “Sometimes a developer doesn’t know his product is facing a problem because he’s unaware of certain aspects of its application. Sometimes the people facing the problem don’t understand the underlying mechanism that’s causing the problem. When awareness of a problem and knowledge of underlying mechanisms come together, you can start testing assumptions about how you’re going to solve it.”

That’s not usually how it goes. Most problems are caught during the extensive material testing in product development. Still, “sometimes in vitro lies to you. It tells you things that will not happen in in vivo. We have learned when we can trust in vitro tests and when it’s best to go into the clinical study before we go to market.” It can, he admits, be painful. “A product is like your own child. But it must go to people whom I trust for testing who are not in love with the product. They must have no vested interest in getting good test results.” While Bock’s name is on dozens of patents for successful restoratives and adhesives, that’s not the only way he gauges success. “When I walk down a crowded street in Germany, I always think, our products are in 10% of these people’s mouths. That’s immensely gratifying.”

Sometimes in vitro lies to you. It tells you things that will not happen in in vivo.

Rudolf Jussel

Head of Department, Advanced Technology Development, Ivoclar

Schaan, Liechtenstein

Education: Graduate engineer in mechatronics, University for Applied Science FH Vorarlberg—Dornbirn (Austria, 1995-99); master of science in manufacturing automation and product design, South Bank University (London, 1998-99)

WHAT’S THE HARDEST part about developing complex electronics for dentists in more than 100 countries? Probably not what you think. “It’s not a big deal to develop devices for the whole world,” says Rudolf Jussel of the technical, regulatory and compliance standards he encounters. Rather, it’s user preferences, which can vary widely by region. “Customers have different expectations of what the product should be. One set of customers may say ‘It should be very simple to operate.’ Another may say ‘We need to feel more in control, we need more buttons.’ In some cases, we end up developing different versions of a product for various markets.”

That makes us appreciate a new product like Ivoclar’s Programat CS6 combination furnace even more. The user interface has been refined to the point where it is, in fact, a truly global product, save for the language onscreen and the power cord. The appeal is certainly universal: Most users can probably mill and crystallize IPS e.max restorations in around 30 minutes. It’s the product of what Jussel describes as a “small but focused” team known internally as the Advanced Technology Group. “We’re looking for innovations. My team doesn’t do product development; we don’t bring it to the end. We’re focused on new ideas and new solutions for the next generation of devices, but we also transfer the knowledge we generate to the product development team and support them. Product developers are our internal customers.”

The Austria-born Jussel, who cut his teeth doing mechatronics in Dornbirn and manufacturing automation and product design in London before moving on to medical devices, joined Ivoclar while completing his master’s thesis in 1999 and hasn’t looked back since. “It’s a very meaningful industry, very innovative,” he says. People might picture him spending most of his time in a lab, but that’s not so, thanks to technology. For the CS6 furnace, for example, thermal simulations were done by computer. Lab time is reserved for more practical work—“screwing things together for proof of concepts,” Jussel says with a chuckle. “We always start with the definition of a problem, knowing the right problem and understanding it.

We do that by visiting our customers and listening to them. Then we try to find as many solutions as possible and pick the best one. Developing products like the CS6 means choosing good compromises between speed, product lifetime and cost, of course. Finding balance sums up to a good product.”

Gilles Richard

Senior Director of R&D, Septodont

Saint-Maur-des-Fossés, France

Education: Ph.D. in polymer synthesis and modification (1996); engineer in chemistry and physics (1992), University of Bordeaux

YOU KNOW those commercials for Transitions eyeglass lenses, the ones that turn into sunglasses when you walk outside? Or Varilux, which are like bifocals, minus the lines? Gilles Richard might still be working on things like that today had he not pivoted to dentistry. After ruling out a car eer in academia, he spent over four years with Essilor, which today is the biggest manufacturer of prescription lenses worldwide. “I discovered that dental composites are similar to plastic eyewear,” he says.

In 2002, he found his way to Septodont, where his most innovative work has to do with biocompatible and bioactive materials, as well as regenerative treatments. While he spends considerable time doing the necessary R&D to maintain Septodont’s leadership position with anesthetics, he brings up Biodentine as perhaps his top achievement to date, describing it as “a pulp therapeutic and a restorative material in the same product.”

The story of Biodentine started before his arrival, in 1998. “A researcher in concrete cement science married to a dentist came to Septodont with the idea of designing a hydraulic, biocompatible restorative material. We created a consortium, including several French dental research teams, together with concrete specialists from civil engineering schools, to develop a commercial product.” One particularly pesky problem: The main raw material, tricalcium silicate, was not available in pure enough form for dental applications. “We had to create, from scratch, a production facility, with high purity grade,” he remembers.

Richard has since filed 20 patents and contributed to 11 international peer-reviewed publications. His team has grown to include 50 researchers with backgrounds in material science, chemistry, biology, toxicology, pharmacology, engineering and more. “The main part of my team is dedicated to new product development,” he says, with “a smaller team looking at new potential technologies to shape what could become new products. This is where we can usually file new patents to protect future innovations.” A third part of the R&D team jumps through the

hoops thrown up by regulatory bodies like the FDA.

Richard’s passion for bioactive materials is encouraged by their growth in the marketplace. “Bioactive dentistry aims to provide care with smart biomaterials bringing more than just neutral function. In that sense, hydraulic calcium silicate materials like Biodentine or BioRoot”—which was introduced in 2015 as a root canal sealer—“not only replace damaged dentine or obturate root canals, but through their chemical structure, they can release elements like ions and hydroxides, which are beneficial for the interface with surrounding tissues.” The next step: regenerative material. “Entire human teeth can already be regenerated in laboratories but remain inaccessible for mass treatments. Regeneration of pulp or dentine will become accessible in the future. This would represent a revolution in dental treatments. The challenge will be to enable the application of these therapeutics to general practitioners and avoid restricted use at hospitals or biotechnology centers.”

Septodont is now in its second generation of bioactive products, Biodentine XP and BioRoot Flow.* Richard himself is approaching 16 years in his current role. Tackling a barrage of new problems, he says, “makes each day different.” As Septodont continues to grow, he devotes energy to making sure his people are aligned and on track. The biggest unifying aspect, though, is “always keeping in mind the end use and the application. An invention without application is not an innovation.”

Regeneration of pulp or dentin will become accessible in the future. This would represent a revolution in dental treatments.”

Reinhold Hecht

Corporate Scientist, Solventum Dental Solutions (Formerly part of 3M Health Care)

Seefeld, Germany

Education: Ph.D. in polymer chemistry, University of Bayreuth (1993)

—

Christoph Thalacker

Division Scientist, Head of Adhesives R&D, Solventum Dental Solutions (Formerly part of 3M Health Care)

Seefeld, Germany

Education: Ph.D. in organic chemistry, University of Ulm (2001)

THERE ARE hardcore scientists, and then there are these guys. Reinhold Hecht, who has contributed to 40 patent families, is a member of one of the most exclusive scientist clubs in the world: 3M’s Carlton Society, the highest recognition of lifetime achievement for the company’s scientists and engineers. 3M currently has 90,000 employees worldwide; the Carlton Society has welcomed only 200 inductees in the company’s 120-year history. Christoph Thalacker has been with the company since 2001 and has more than 30 patent families to his credit, plus dozens of published articles. Both have now have joined Solventum, the new independent health care company spun off from 3M.

Solventum’s culture scales both up and down, from small labs to giant factories, and fostering that culture seems to come as much from the boots on the ground as from the C-suite. “You have to make sure your product is faster, easier, better—and not a compromise,” Thalacker says. Hecht talks about the luxury of being able to leverage “our broad technological capabilities,” but always in the service of dentistry.

One thing about top-echelon researchers: They must have skin thicker than everyone else’s. They seek out contrary opinions and rejection in a way that’s anathema to most criticism-averse people. Only the best solutions win—and to them, that’s the fun. “When you’re on a development project from the first experiments until after launch, when you can show your new baby to the world, no day is like the other,” Thalacker says. Naturally, they line up eagerly for kudos or criticism from their toughest critics—doctors—during development, or even before it begins. “We have several practicing clinicians within Solventum. They are our first sparring partners when discussing new ideas or prototypes.”

Some recent innovations include RelyX Universal resin cement and 3M Scotchbond Universal Plus adhesive. “The combination of these two simplifies all aspects of the resin cement workflow and offers a solution that addresses virtually all dual-cure adhesive and self-adhesive indications,” Hecht says. Thalacker calls Scotchbond Universal Plus “the biggest launch I was directly involved with,” one complicated by the exigencies of the pandemic. “As doctors now take high bond strength for granted, we focused on features that went beyond adhesion: radiopacity to facilitate interpretation of X-rays, the ability to bond and seal caries-affected dentin for minimally invasive preparations, a formulation free of BPA derivatives and several others.”

Research like this isn’t cheap, and someone has to pay for it whether it’s successful or not. That means balancing intellectual curiosity with a results-based approach. “To work on defined projects for next-generation products is an important task of my research work,” Hecht says. “But as a corporate scientist, I must also look for megatrends that may [affect] our business.” Adds Thalacker, “Early on, it’s important to screen different technologies [for] whether they may be able to solve a challenge for our customers. The closer a product comes to market launch, the more I work on optimization of certain details, like adjusting the viscosity for handling.”

Another challenge: focusing on what’s solvable today while simultaneously working on tomorrow’s advances. “Safety and a minimized impact on the environment are important during all phases of development, starting with the selection of raw materials,” says Thalacker, whose team tests all materials for biocompatibility prior to the first in vivo use. He points to the amine-free dark cure initiator in resin cements “which also enabled better color stability and esthetics.” Then there’s the miniaturized automix syringe for RelyX Universal Resin Cement that reduced waste by over 80 percent compared to older designs.

Both men cite their collaborations with dentists as among the most fulfilling aspects of their work. Even after 26 years, Hecht says, “it’s satisfying and exciting.” The two also point to their excitement over what’s possible in the years ahead. “Dental materials are still an active area of research where significant progress can be made, even though we have very good materials nowadays,” Thalacker says.

We have several practicing clinicians within Solventum. They are our first sparring partners when discussing new ideas or prototypes.

Sunny Skaria

Chief Research Scientist, Pulpdent

Watertown, Massachusetts

Education: Ph.D in polymer chemistry, National Chemical Laboratory, Pune (India, 1996); postdoc, Pierre and Marie Curie University, Paris (1997-98); postdoc, FMF–Albert Ludwigs University (Germany, 1999–2002)

GREATER BOSTON is home to more than 1,000 biotech firms. Despite the shift to remote work, most science is still done in actual labs by actual humans. Little surprise, then, that Sunny Skaria has chosen to work smack-dab in the middle. If you want to innovate, you go where the innovators are. He leads a small team of Ph.D.s, chemical engineers and chemists at Pulpdent, which has positioned itself as the leader in esthetic bioactive dental materials.

But Pulpdent isn’t part of the latest tech wave, and Skaria isn’t new to dentistry. The company was one of the earliest members of Boston’s science community. Founded in 1947, it shifted into high gear as the region’s science industries exploded in the 1970s. Skaria parlayed a Ph.D. in chemistry (plus university training in polymer synthesis and characterization) into a research scientist gig under professor Scott R. Schricker at Ohio State’s College of Dentistry. “That’s where I learned about dentistry and dental materials,” he says. “My expertise in synthesizing monomers and polymers, especially urethane monomers and biopolymers, led me to my current position.”

His research at Pulpdent has so far generated six U.S. patents and research articles and is responsible for the development of new urethane dimethacrylate monomers used in many Pulpdent products: “These include the synthesis of a patented molecule that makes dental resins more fracture-resistant; the development of esthetic, load-bearing bioactive restorative materials; and the development of a methacrylate-functionalized calcium phosphate with bioactive properties.” Those advances led to the development of Tuff-Temp Plus provisional material, Activa Bioactive restoratives and the bioactive Crysta MCP technology in Lime-Lite Enhanced and Activa Presto. Of those, Skaria says he’s proudest of Activa Bioactive, “the first FDA-approved bioactive esthetic dental product.” It’s this string of successes, he feels, that really put Pulpdent on the map as “a premier company in the bioactive dentistry market.”

His research is different than if he worked for a company with a wide breadth of products. It’s guided more by Pulpdent’s philosophy than market trends, and the company seems perfectly content to blaze a trail, even if it means waiting for others to catch up. “Sometimes we identify specific needs, but in general, we believe in developing materials that transition dentistry from a passive model intended to do no harm to an active approach that delivers direct benefits. You might call those bioactive or biomimetic materials,” Skaria says. “The research decisions

follow this idea. We’re developing materials that encourage remineralization of damaged teeth, support natural healing and discourage the biofilm and enzymatic activity that compromise composite dental restorations and lead to their early failure.”

Between breakthroughs, there’s lots of meticulous work to do. “New discoveries are usually evolutionary,” he says. “One set of experiments informs the next step, one discovery leads to another.” In his view, bioactive esthetic materials are poised to gain even more traction as clinical evidence builds. He’s happy to be part of what Pulpdent’s bioactive evangelists might characterize as a genuine movement in dental materials. It certainly feeds his appetite for discovery. “This is a fascinating field, and we’re doing things that have never been done before.”

We are doing things that have never been done before.

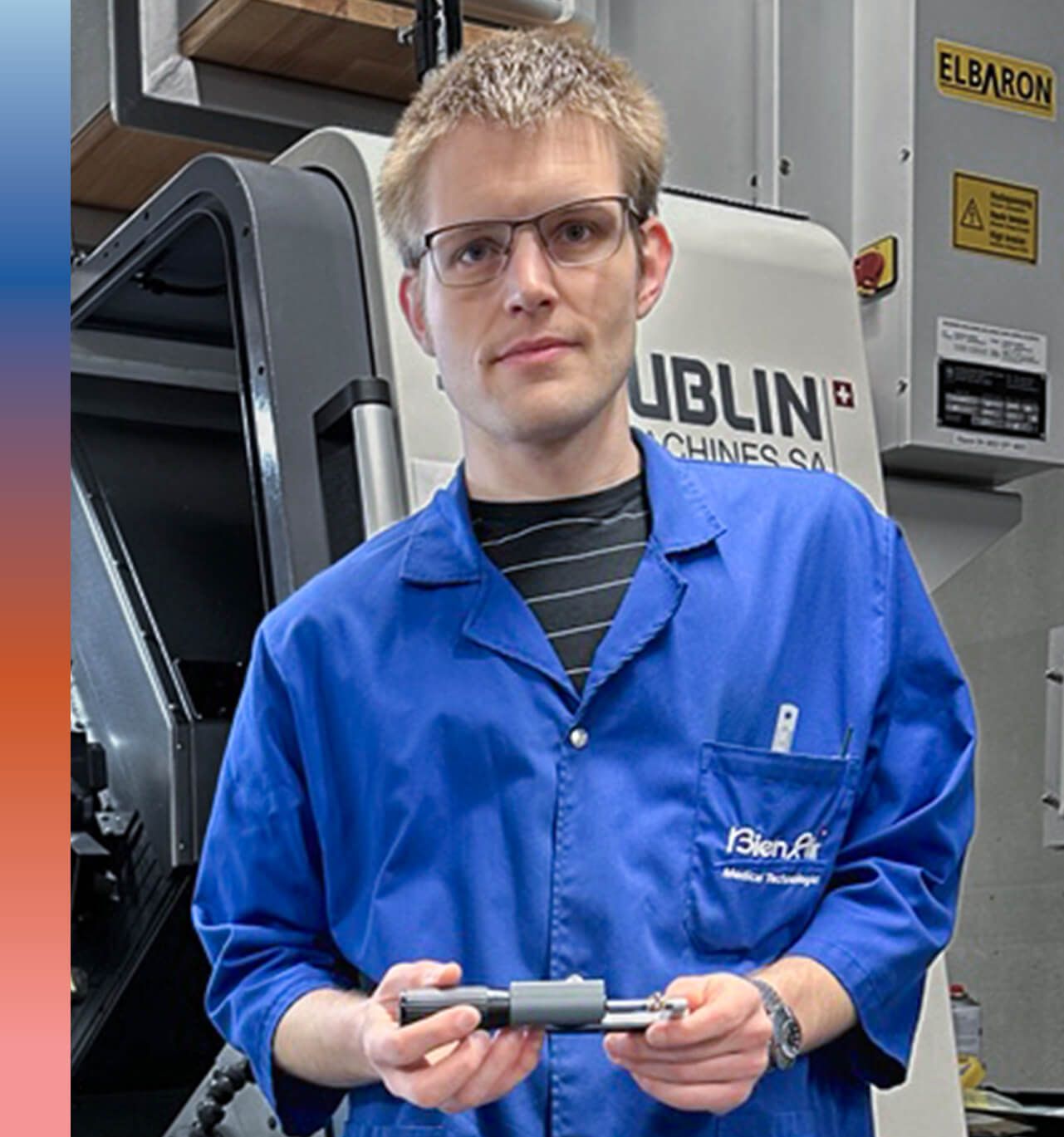

Sam Mosimann

Chief Technology Officer, Bien-Air Dental SA

Bienne, Switzerland

Education: Micromechanical apprenticeship, BBZ-CFP, Bienne, Switzerland; B.S., Bern University of Applied Science, Bern, Switzerland; master of science in biomedical engineering, University of Bern

HANDPIECE DESIGN and manufacturing is like walking a tightrope of conflicting priorities. Just ask Sam Mosimann. Everyone wants smaller handpieces, but “the smaller you make a bearing, the smaller the load it can withstand, the shorter the life.” Everybody wants low cost and high performance, but “from an engineering perspective, these are competing energies. If you want something produced fast and with quality, it won’t be cheap. If you want something cheap and fast, it won’t be with quality.”

The answer, he says, is part engineering and part intellectual curiosity. The answer might also involve geography: Bien-Air is situated in the Jura Arc spanning Geneva to Basel. You might know it as Watch Valley, and Omega and Rolex are “right up the street,” Mosimann says. So are top medical companies like Johnson & Johnson, Medtronic and Stryker.

“We’re a 90 percent export country of medical, industrial and luxury mechanical products,” Mosimann says. “Our applications are specialized. We must be masters of not only our products, but [of] the machines we use.” Unlike many of their watchmaking neighbors, Bien-Air is still family-owned. That changes development timelines. “Our question is not what it will cost, or how long it will take; it is what it will take to be the best.”

Case in point: Bien-Air’s development of the Nova, which has the smallest head of any electric handpiece incorporating a four-port spray. Prior to its creation, the company had nearly reached the limits of small bearings that would last. Mosimann, an incessant knowledge hound, remembered a type of gearing used in helicopters, cars, machine tools and Formula 1 transmissions that was efficient, with power density improvement, good acoustics and minimal loss of heat energy, yet inexpensive to assemble.

The next step was choosing a material. The answer was stainless steel: better than titanium in this application, since it dissipates heat and transmits less vibration. The final issue: creating a machine that could produce the exacting geometries in the highest-grade stainless steel. “Luckily for me, we are in Bienne, where the largest industry for machining companies to make small parts exists.”

On one hand, Mosimann is deadly serious about smart engineering, cutting-edge materials and precision manufacturing. On the other, he wears it lightly, saying he’s just “one small part in a very large and capable team.” Likewise, Bien-Air is proud of its Swiss heritage but doesn’t make it the center of its brand. The young company (by Watch Valley standards) was founded by Mosimann’s grandfather, David, in 1959, and is owned today by his son, Vincent. Sam Mosimann tells a story about his grandfather’s invention of its first electric handpiece in the 1990s. When word came back that American customers were requesting greater visibility, David made a spot adjustment to the design. “He then handed the new schematic to the mechanic. It was a powerful experience for me. My grandfather was, in that moment, the CEO, CTO and CFO. Who knows how long that little adjustment would have taken in a more traditional company structure.”

Like grandfather, like grandson: Every part of Mosimann’s products must pull its weight. He points to the use of aerospace PVD—physical vapor deposition—in the Nova handpiece to extend the life of the chuck. “We use a principles-first approach to determine if innovations in other industries can help us get closer to meeting the needs of the dentist.” The iOptimaINT, incorporating restorative high and slow speed, rotary and reciprocating endo, implant and perio, is designed for large and multispecialty practices wanting to treat cases in-house. “Our company is very similar to our customers’ business: It’s not a board of MBAs running a dental practice. We are a mechanical company, and that remains our standard. Now that I think about it, most of the people in our company are engineers, including our CEO.

Innovation often competes with short-term profitability. I’m lucky to be in a situation where we can take risks.

Wouter Mollemans

Head of Software R&D, Envista

Mechelen, Belgium

Education: Ph.D MSc in civil engineering and electronics, KU Leuven (Belgium, 2006)

PEOPLE WHO FEAR that artificial intelligence is on a collision course with humanity’s very survival aren’t necessarily anti-progress cranks. A 2023 letter from the Center for AI Safety, signed by high-ranking founders and executives from the likes of Google and OpenAI, compared the threat to nuclear war. Cooler heads say the biggest risk isn’t society embracing AI too quickly, but rather developers’ reckless abandon, resulting in applications that erode people’s ability to think critically. People like doctors, for example.

Luckily, Wouter Mollemans is among those devoted to ensuring that AI doesn’t become a runaway train. “I’m a big fan of looking at this stage of AI machine learning algorithms as an ‘assisted intelligence’ tool,” he says.

Don’t misunderstand. Mollemans isn’t talking about pumping the brakes. “I’m convinced that assisted intelligence can result in overall better dental diagnosis and treatment.” AI algorithms are the preeminent focus of his research team—research shaped at every stage by the involvement of actual dentists. To this end, the company’s UX (user experience) analysts leverage a variety of tools to capture human input: user personas, shadow visits, journey maps, design mockups and interviews. All of it is done with the understanding that AI alone has limited value, but AI in the hands of skilled dentists is capable of extraordinary things.

Mollemans is, as you’d imagine, a dental guy through and through: “Medicine has always fascinated me, but my love for math and analytics is equally strong. Digital dentistry gives me the unique opportunity to blend these two passions harmoniously.” He leads a team that includes engineers, UX analysts, software developers, testers and DevSecOps. In the last year alone, he presided over the launch of AI enablement in Envista’s DTX Studio software platform, which also trickled down to its DexAssist software solution, enabling users to identify up to six dental findings on 2D X-ray images with just one click. Obtaining regulatory approvals before going to market required designing an extensive clinical evaluation involving 30 American dentists to demonstrate that use of the AI tool generatedan improvement in correctly labeled findings.

If he sounds like a calming voice of reason when it comes to AI, it’s perhaps because his youthful energy is tempered by decades of hard-earned wisdom. Unlike the twentysomethings diving into AI careers today, his early days were quaint by comparison. “When I started my Ph.D. program, we had one shared computer we could use for testing algorithms. Today, these algorithms can be performed on any PC in less than a second.” His research included developing an algorithm that predicted how a patient’s face would change in three dimensions after maxillofacial surgery. “The first AI algorithms were popping up, but the computational complexity was often too high to result in applications that could run on a normal computer.” Faster computers helped Envista launch its first machine learning–based algorithm six years ago.

Mollemans is insistent that the cloud, while less sexy than AI, should be nurtured with similar vigor. “Having access to patient data from anywhere, easily sharing it and coming to a shared treatment plan will be fully realized only when multiple software solutions work smoothly together.” For that to happen, he says, “I want to advance the industry toward standardized file formats.” The upcoming release of the DTX Studio platform, where all 2D and 3D images of a patient can be stored, viewed and diagnosed in a single software solution, will also have new features for creating a 3D implant treatment with surgical drill guides or for exporting the plan to Nobel Biocare’s X-Guide navigation system.

After 20 years, Mollemans’s excitement remains undimmed. “I’m still discovering new potential daily. It feels like a never-ending game, where new superpowers are available at every level.” If he has his way, those superpowers will be deployed and managed under the watchful eyes of dentists. He and his team are working to make it more accessible every day. “You do not need to be a digital expert to embark on this journey, he says. “Embrace the digital wave to stay ahead and leverage your daily work and life.”

We must be cautious in our approach to using and evaluating AI algorithms. Men and machines should not compete to be the best at a certain task.

Timo Müller

Vice President, X-ray Division, Planmeca

Helsinki, Finland

Education: M.Sc (Tech) in machine automation, Tampere University of Technology, 1989

YOU CAN’T KNOW where you’re going unless you understand where you’ve been. Timo Müller has devoted his entire 34-year career to dentistry, focusing exclusively on imaging since 2004. Having presided over massive technology shifts, he has a deep appreciation for how X-ray equipment has evolved, as well as strong insights about what’s to come.

When, for instance, can dentists expect a true 3D intraoral X-ray? “I personally don’t believe in a true 3D intraoral X-ray,” he says. “True 3D imaging needs to have image samples obtained across 180 degrees plus a beam opening angle around the target being imaged. This is just not possible.” He characterizes today’s next-best thing, tomosynthesis, as a “kind of ‘2.5D’ ” for those who want it. “The benefit is not that great compared to traditional intraoral imaging, and it isn’t a true 3D image. Maybe someday there will be an AI-based tool to fill in the missing ‘0.5D,’ but would this still fit in the modern patient care flow?” He’s more in favor of the partial field of view (FOV) functionality found in CBCT units.

Müller oversees a team ranging from product developers to marketing product managers. The structure helps keep projects on track so the finished product aligns with customer expectations. It also frees up Planmeca’s mechanical designers, electronics designers, embedded software developers and testing specialists to concentrate on pushing boundaries. “Their passion is to invent and develop something new,” he says. That is, of course, a vast oversimplification of how much granular work goes into it. “The dental imaging field is heavily regulated. In the years I’ve been in the industry, regulation has developed increasingly toward more product-related risk analysis.”

Here’s something you wouldn’t necessarily expect: Product longevity is also baked into the development process. It’s unusual to hear about that in an age when tech users are accustomed to replacing their phones and kitchen appliances every few years. Müller says making long-lasting products starts on the outside, with durable and sustainable materials, and extends to the inner workings (“the secret to Planmeca products’ long lifespan is the technical platform that can be kept up to date with clever software”).

He’s particularly proud of the Planmeca Viso family of imaging units—“a major advance for us. The workflow and patient positioning with the help of integrated cameras and the rear head support make the patient experience smooth and the quality of the resulting image predictable.” Software like the Romexis platform, he says, is getting a shot of adrenaline with the incorporation of “AI tools that provide faster workflows and support for diagnosis.”

That constant march toward smarter, better, safer and more sustainable tech seems key. “When I joined the company in 1990, all dental imaging was film-based. Our first direct digital panoramic unit was introduced in 1995, and 10 years later we introduced our first 3D imaging unit. This was also a time of transition, when demonstrations at exhibitions shifted from the imaging unit itself to the software in which the images are displayed.” Now that the development and supply chain problems of the pandemic are largely past, Müller’s full attention is on the future. “Recent developments in radiation dose reduction and image quality as well as the possibilities offered by AI are personally thrilling.”

The transition from film-based to digital and further to 3D imaging has been one of the key things that has kept me driven.

Christoph Meier

Head of R&D Technology Development, Global Research & Development, Kulzer

Hanau, Germany

Education: Ph.D. in chemistry, Technische Universität Darmstadt, 2017; M.Sc., 2013; B.Sc., 2011

THERE’S NO WAY around it: Developing innovative dental materials is expensive, especially the kind of which Kulzer’s Christoph Meier dreams. “This is a big difference to other industries,” he says, “in which you often have to deal with strict limitations of costs and cannot start being so creative in terms of new chemical solutions.”Too much is at stake to cut corners during any stage of the process. Under his watch, Kulzer leverages corporate synergies and economies of scale to do ambitious R&D, yet still bring products to market that deliver great value. How?

By applying lessons from other industries. Meier is a specialist in polymer-based composite materials. “At Airbus, I developed high-temperature carbon-fiber reinforced composites, and at Hilti, two-component fire protection coatings. The chemical background is similar, so the transfer between these fields is ‘only’ the final application.” Polymer-based composites, he explains, always follow the same principle: The final composite is a mixture of a polymer-based matrix and other ingredients, which exhibit different properties than the single substances.

Another thing you can do is lean on your connections. In this case, Meier doesn’t have to look far. His team regularly collaborates with other R&D professionals from shareholder Mitsui Chemical’s extensive network of companies in electronics, automotive and other fields. “Together, we try to find synergies inside Mitsui, develop custom-made chemical solutions and try to transfer them to the dental field,” he says. Because discoveries at one entity often fuel advances at another, there’s a genuine esprit de corps among researchers, which has resulted in several patents, plus cost savings that can be passed on to consumers.

Meier’s work centers on developing new technologies, whether raw materials, devices or processes—“technology platforms that can be used for several product variations.” Consider his involvement in the ONE line of single-shade composite materials. Not only are they a clinical success, but they satisfy Meier’s directive that these platforms contribute to simplification for practitioners. “I’m especially proud of the new flowable Venus Bulk Flow ONE,” which he says “shows a significant advantage by combining the exceptional ONE-shade effect with bulk-filling properties—curing depth of at least four millimeters—without the need for an additional capping layer.”

There are, inescapably, a lot of steps involved. As such, product development times vary wildly. There’s prototyping, careful evaluation, market analysis and product viability vetting, plus customer feedback from their dental advisory boards before a new process is greenlit. Even that summary is a vast oversimplification: It doesn’t include regulatory hurdles, which Meier says make things increasingly complex, like Europe’s recent transition from MDD (Medical Device Directive) to MDR (Medical Device Regulation), which is far broader in scope. And that’s just Europe.

Meier remains passionate about chemistry and materials, able to talk for hours about one advance after another, like Kulzer’s unique Tricyclodecane (TCD) matrix used in the Venus Diamond/Pearl ONE composites. “[The] molecules vibrate less and take up less space than traditional matrix molecules. Minimal movement results in significant benefits such as low shrinkage stress, which reduces the risk of marginal gap formation and secondary caries. In addition, the high level of cross-linking in the TCD matrix increases the strength and durability of the composite.” Still, the teamwork, the processes and the birthing of new products brings out the people-pleaser in him. It’s a “great joy,” he says, especially “when [we] push new technologies that could solve unknown pain points. Seeing ideas accepted by customers is great motivation.”

We’re always looking into new technological fields that do not yet fit certain product strategies. There is no fixed time frame for these, but they are necessary to find creative new solutions.

Michael Couch

Senior Portfolio Manager, Dental Products, Midmark

Versailles, Ohio

Education: Bluffton University, business (BA, 2007; MBA, 2010)

MICHAEL COUCH IS a minority among the scientists, researchers, engineers and CTOs on these pages. His job title gives it away: He’s in marketing and has an MBA, not a Ph.D. But the sausage gets made differently for different products, and Midmark doesn’t create restoratives; it crafts environments. (Midmark Synthesis cabinetry landed on our Products of the Year list in 2023.) For lack of a better simplification, Couch is its dental environment execution whisperer. That means gathering enormous amounts of clinician feedback, distilling it into actionable data and parceling it out to his team as they tweak current products and dream up what’s coming next.

“Midmark is above all a design company, and good product design always starts with the customer,” he says. “To understand customers and their needs you must understand their current realities and goals.” It’s more demanding than it might sound. When it comes to dental materials, science can make water boil only so fast. But for products like cabinetry (or instrument processing or mechanicals, also part of Midmark’s portfolio), there’s no excuse for not delivering products that could help people perform better. Steel and glass don’t change much, but our understanding of how to command them in service of ergonomics and user preferences relentlessly evolves.

Midmark’s research is based on both subtle and not-so-subtle cues from users. What users tell Midmark is just as important as what they don’t, Couch says. The company looks for glaring bottlenecks but also nearly imperceptible user frustrations while watching users and studying their movements. “Concepts like ‘design thinking’ require empathizing with the end user and their needs. If we’re solving problems that aren’t important to users or have little positive impact on them, we’ve failed.” Couch revels in being involved in any process that starts with “pushback and doubt that we might not actually be able to provide a solution,” but ends up successful.

True, Midmark products also look great, but Couch is quick to answer about how he’d break a tie between form and function. “Charles Eames said, ‘What works good is better than what looks good, because what works good lasts.’ If we must lean one way, we will lean toward a solution doing its job well first, because ultimately our objective is to provide solutions that provide better outcomes, keep our clinicians safe and healthy, and enhance the patient experience.” As he sees it, the onus is on him to “communicate a clear vision for product development” to his team, so those kinds of choices are made early.

Thorough testing and evaluation extend to things like Midmark vacuum systems as well, which are now created using advanced software that helps engineers better visualize air and water flow to assess long-term product durability in the real world. Such analysis caused Midmark to add two inline filters to reduce large moisture particles and fine particulates that come through the system in order to increase the life of the product. “We’re side by side learning with clinicians,” Couch says. “That fuels my passion for what I do.”

Midmark is above all a design company, and good product design always starts with the customer.